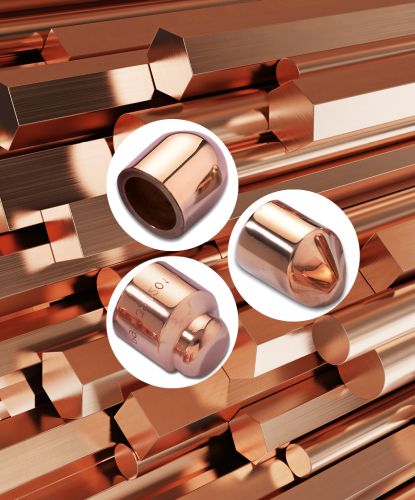

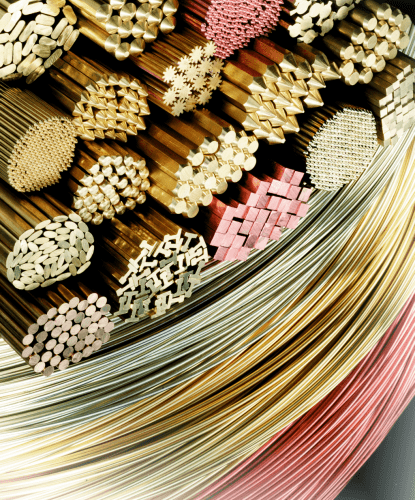

Hardiall® range of spinodal alloys are wrought copper nickel tin materials :

-Very high strength, heavy duty and high load capacity CuNi15Sn8 (C72900) version called Hardiall®

-High strength, heavy duty and high load capacity CuNi9Sn6 (C72700) version called Hardiall Eco®

Both are designed for high performance applications where excellent high friction wear resistance, galling and toughness requirements are needed. They are easily machined into complex components whilst being environmentally friendly, being both lead free and beryllium free, and are easily recyclable.

Lebronze alloys being fully integrated for all processes mitigates supply chain risks offering semi-finished products but also is able to propose ready-to-use finished products.

Hardiall® Materials Properties and Benefits

Standards:

Hardiall® wrought CuNi15Sn8: UNS C72900; ASTM B929. CW355H EN 12163.

Hardiall® CuNi15Sn8 complies with and exceeds the aerospace standards (AMS 4596, 4597, 4598) as well as Oil & Gas standards such as NACE MR0175

Hardiall® is the ideal substitute to Beryllium Copper CuBe2 C172000 CW101C as per EN 12163: Hardiall® CuNi15Sn8 reaches similar mechanical properties as well as superior surface properties and workability.

Hardiall® is a direct equivalent to Toughmet® 3 and is an ideal proven track record solution. Extensive testing ensures that Hardiall® is in full compliance with the relevant specifications: in that regard, using Hardiall® can help high-end industries mitigate their supply chain risks.

Hardiall Eco® wrought CuNi9Sn6: UNS C72700

Hardiall Eco® wrought CuNi9Sn6 has been developed to master the technical, economic and ecological constraints for heavily load bearings in construction mining, automotive and industrial applications.

Hardiall Eco® is the ideal substitute for steels, casted leaded bronze or manganese bronzes as well as casted spinodal copper nickel tin alloys like C96900 CX105, C96970 CX90 ensuring the adequate fatigue strength.

| Hardiall® and Hardiall Eco® Key features & Benefits |

| High strength and hardness |

High pressure and load resistance capacity |

| Low friction & galling resistance |

Ductility and fatigue strength |

| Excellent wear resistance |

Pitting, cracking, spalling resistance |

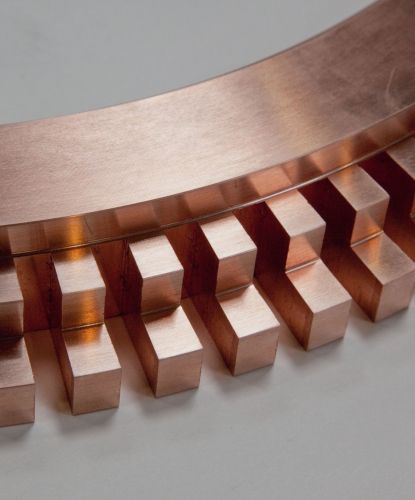

| Excellent machinability |

No Hydrogen embrittlement |

| Non-magnetic |

Corrosion & Erosion resistant |

| High performances within temperature range -125℃ up to 300℃ |

Performing especially at slow but also at high speeds |

| Dimensional stability |

|

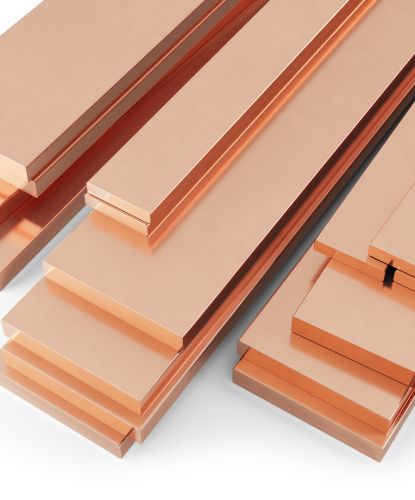

HARDIALL® (Hardiall® and Hardiall Eco®) materials are available in two tempers:

- TX temper (wrought hot worked and spinodally hardened temper)

- TS temper (wrought hot worked, cold finished and spinodally hardened temper) offering the highest level of mechanical properties.

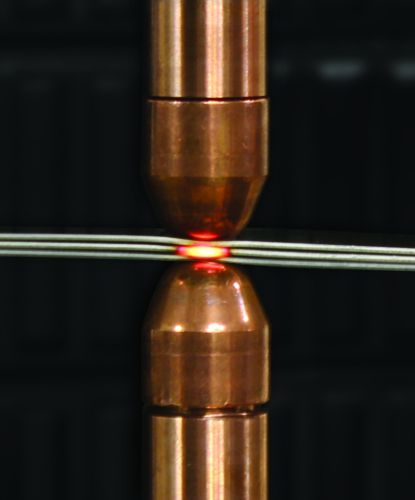

These Copper Nickel Tin spinodal alloys have a specific metallurgy enabling a spinodal decomposition and thus providing a unique combination of material properties.

High mechanical properties are reached by hot working or a combination of hot and cold working processing and are drastically enhanced with a final heat treatment controlling the spinodal decomposition.

For example, a threefold increase in the yield strength over the base metal is achieved after the spinodal decomposition treatment.

These heat treated "spinodal alloys" are a very good bearing and bushing materials due to their its high strength, low magnetic sensitivity, excellent machinability, maximum corrosion resistance

Additionally, their high surface resistance under impact loads and especially in critical lubrication conditions, when compared to conventional bearing materials it provides longer lifespan, higher reliability and better construction flexibility.

Hardiall® can be used under various environmental conditions, under high and very high loads at low and high speeds, lubricated, periodically lubricated or little lubrication in the temperature range from – 125 °C to + 300 °C in combination with different materials.

These materials have already been approved by numerous OEMS or are compliant part of an ongoing qualification process in highly demanding industries such as Aerospace and Oil & Gas.

HARDIALL® (Hardiall® and Hardiall Eco®) range of spinodal alloys key applications by industries

Whatever the industry considered, HARDIALL® range of spinodal alloys, thanks to their unique combination of properties, are preventing unpredicted failures, ensuring a longer lifespan compared to traditional materials.

HARDIALL® range of spinodal alloys outperform steel and manganese bronze by increasing the durability, reliability, and lubrication cycles of highly stressed/loaded solicited bushings and bearings.

The above enables the prevention of costly Aerospace AOG or maintenance associated production downtimes in Oil & Gas, Mining, Industrial production.

Aerospace

Actuation systems, friction bushings and bearings for primary and secondary flight controls, wheels and brakes and various aircraft systems attachments.

In landing gears, bushings and bearings are required to operate under severe conditions high loads, increasing hydraulic systems pressure.

|

Aerospace

|

Customer specifications |

| ABS 5849 |

| ABS 5152 |

| MTL 4112 |

Construction Mining

Heavy Mining Equipments and Vehicles excavators, haul trucks, mining shovel and draglines, continuous miners Pivot Bushings and Bearings, Tri-Cone Rock Bit Roller Cone, Reamers HDD Tools Bushings, Thrust Washers

In mining equipment, bushings and bearings are highly stressed/loaded solicited components operating in aggressive media with harsh minerals.

Hardiall® CuNi15Sn8 and Hardiall Eco® CuNi9Sn6 demonstrate excellent lubricity, wear and galling resistance making it the ideal material for bushings and bearings.

Hardiall Eco® CuNi9Sn6 is the material of choice for applications combining ecological and economical constraints with moderate to high load capacity while Hardiall® CuNi15Sn8 should be used for the highest mechanical properties requirements.

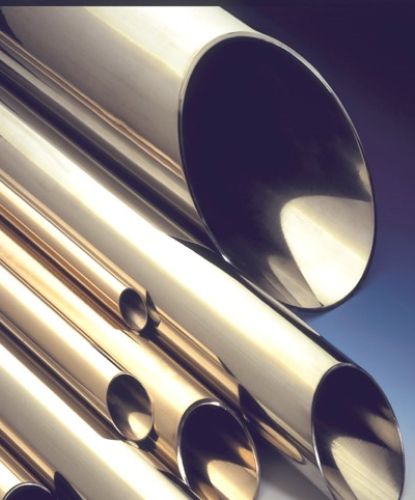

Oil & Gas

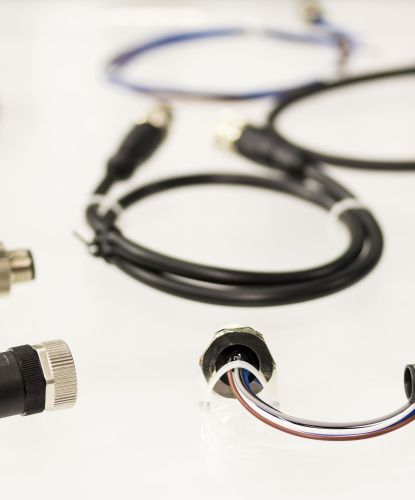

Onshore Artificial lift sucker rods, valve guide couplings

Offshore Subsea Wellhead Controls, Manifold, Mud Pumps, LWD and MWD Components, HDD tools, cdrill bit, bearings, bushings, thrust washers , ROV hydraulic connectors, Valves components Trim.

Hardiall® is specifically used in offshore subsea applications where the continuously increasing depths create new challenges to master high temperatures high pressure along with aggressive media like sour environments.

|

Oil & Gas

|

Customer specifications |

| 22-000119-03 |

| CU07 CU08 |

| MS013 |

| WN 135 |

| 6000062 |

| MS 145 |

| 100082256 |

| 100679610 |

| M 40131C |

| 50 2L 50 2D |

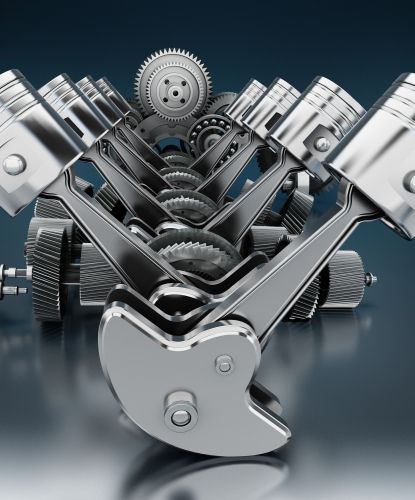

Automotive

Racing Cars, Passenger Vehicles Powertrain Components (valve guides, plain bearings, bushings)

Braking and Steering Systems (Brake caliper bushings, Steering bushings)

HARDIALL® range of spinodal alloys have a high strength and hardness, excellent machinability, maximum corrosion resistance and thus high wear resistance under high loads, especially in critical lubrication conditions. Hardiall® is a key material for such technical issues. Motorsports, the forefront of innovation. Compared to conventional materials, Hardiall® enhances design optimization, with reduced mechanical clearances. It boosts performance and reliability, mainly used in powertrain, steering and braking systems.

Other applications

Many other developments in Defense, Industrial, Metallurgy, Renewable Energy and Ship Building.

HARDIALL® range of spinodal alloys offer: unlocking potential for high strength copper alloys

Based on your specific application HARDIALL® range of spinodal alloys can offer thanks to its unique combination of surface and mechanical properties a technical and economical valid alternative Beryllium Copper, Nickel-based Corrosion Resistant Alloys (CRAs), Titanium, Precipitation Hardening Steels, Stainless Steel and Manganese Bronzes

It is a material of choice for design engineers solving challenges for stringent requirements and environments, such as performance friction bushings and bearing cages

Working closely with our partners, alongside customers, engineers and experts within the approval bodies, where we strive to exceed markets expectations

These Copper-Nickel-Tin products are enhancing existing alloys high-performance alloys portfolio in addition to Aluminum Bronzes and age hardening Copper-Nickel-Silicon alloys: of high strength applications

• By delivering high-quality products and services

• By developing new services such as alloys advisory for prescribers, co-design and TCO optimization with semi-finished or near-net-shape components.

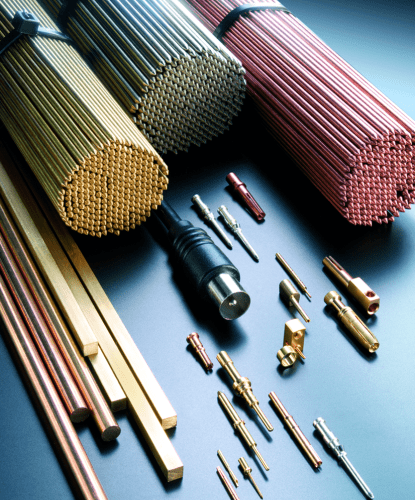

HARDIALL® benefits from a fully integrated manufacturing process and a global distribution network:

Lebronze alloys internal processes include casting, hot and cold working stages, heat treatments and non-destructive testing. Being fully integrated ensures reactivity and complete traceability.

We span and support the complete supply chain from major OEMs all the way through to local machine shops offering local service along with a personable approach directly or thanks to our worldwide partners network.